SSAB Borlänge, Continius Annealing Line, Sweden

Automation: increasing the overall output and the product quality

- Date: January 2017

- Customer: SSAB EMEA AB, Borlänge, Sweden

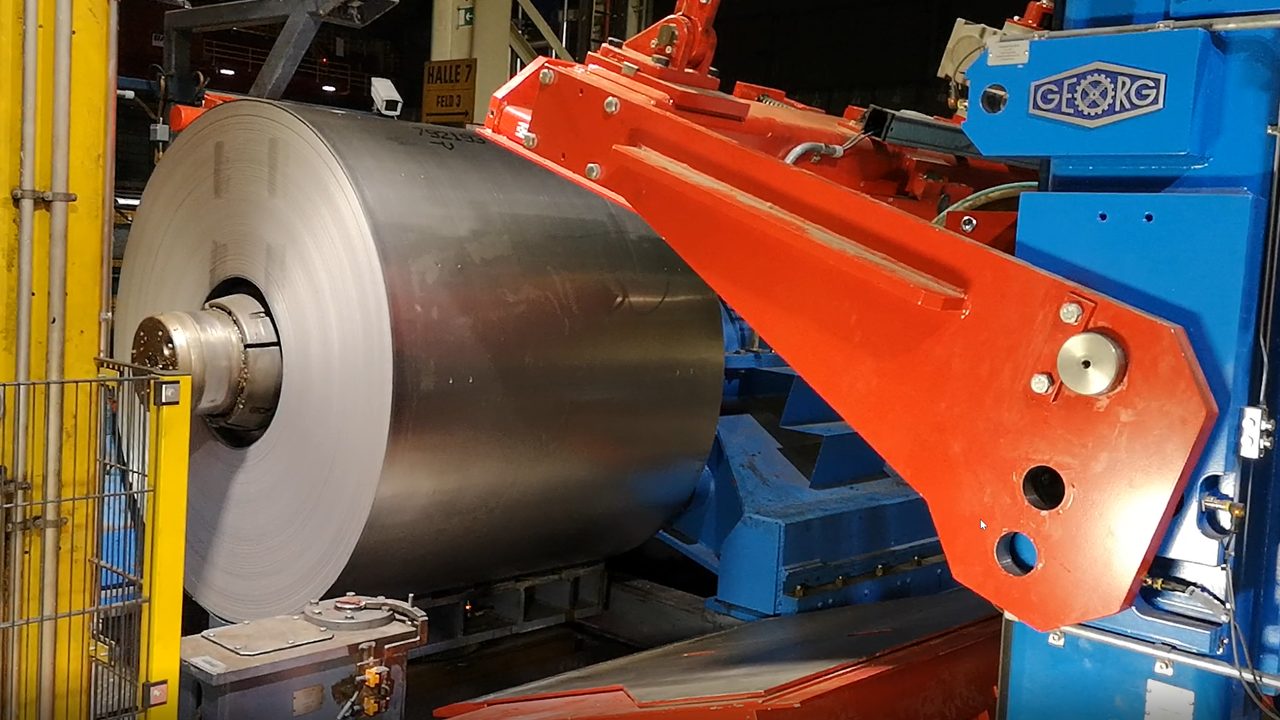

- Project Typ: Automation of continous annealing line

About the Project

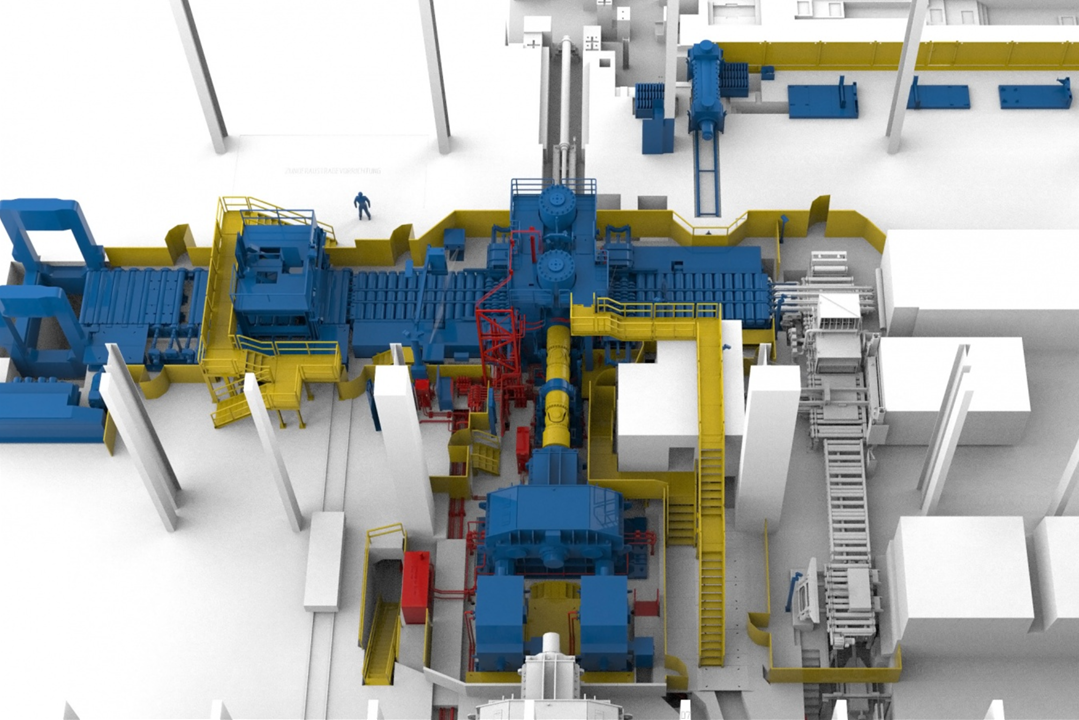

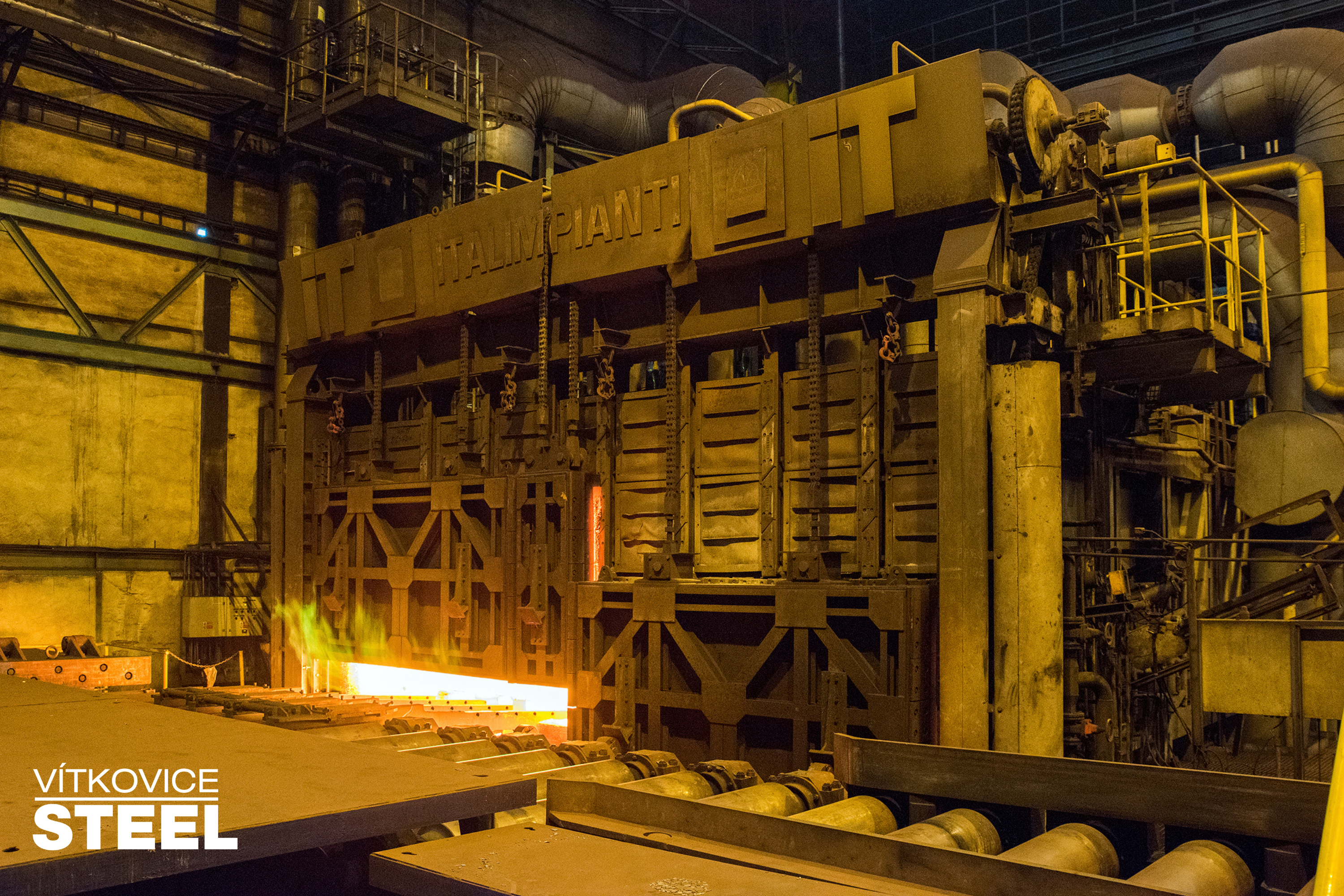

In the year 2017 SSAB started a project with the aim of increasing the overall output and the product quality in the continuous annealing line. As this was not a traditionally “Turn Key” project but a continuous improvement process, SSAB was looking for an experienced automation partner and found it in pa-innovations GmbH. Since this, following major improvements could be realized on the line which is specialized to high-strength steel:

- Implementioin of a new tension control concept in the process section (furnace)

- Drive optimizations and increasing of the maximum line speed in the process- and exit section

- Implemention of an Anti-Spin-Control for the furnace roll drives (Prevention of scratches)

- Improvement of weld seam tracking accuracy

- Replacement of the filling level measurement in the loopers

- Implementation of the Level 1 interface including switching-over concept of the existing temperature controllers to the new Level 2 furnace model

- Automation of the new heat exchangers (flow- and temperature control) for the strip cooling system

- Implementation of the drives for the extended preheating section as part of the tension control of the process section

- Optimization of the rotary shear in the exit section

By implementation of these measures, the improvements aimed for the customer were achieved to the highest level of satisfaction.

The cooperation between SSAB and pa-innovations is characterized by the joint development of the project-solutions and the detailed specification of the solution concepts by control technology expertss and simulation experts at a high technical level and the use of the most modern solution approaches. The implementation of the software on the existing Simatic S7 system is carried out entirely by pa-innovations. Due to the success of this partnership combination, SSAB has already secured the support of pa-innovations for further projects.