Testfield and Training

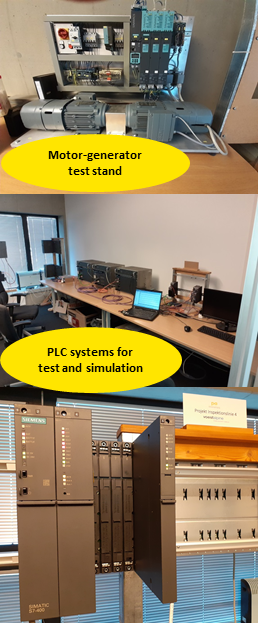

Testfield:

Depending on the project size, tests are carried out in our own test field at the pa-innovations branch. For large projects, own test areas are rented in order to be able to set up and wire up the complete control cabinets, consoles, visualization stations etc. The application software is already analyzed in different test cases as during commissioning by means of a measurement data acquisition system (iba-PDA). In most cases the test configuation is already used for the training of maintenance engineers and control staff in the test field.

Training:

pa-innovations offers extensive training for maintenance engineers and operators.

The key to success in operating a plant is the necessary extensive knowledge of the maintenance engineers as well as the operators. For this reason, training courses are offered on various topics depending on the available knowledge and tasks of the customer’s personnel:

- Basic knowledge of programming

- Plant specific relations to automation configuration

- Structure of the application software

- Fault diagnosis and fault analysis

- Operating and controlling the mill

- Basics of the used automation hardware (exchange of hardware etc.)

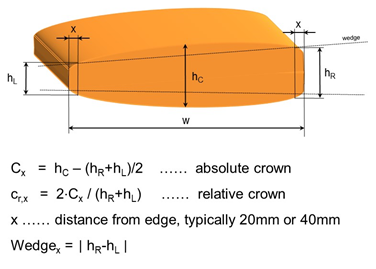

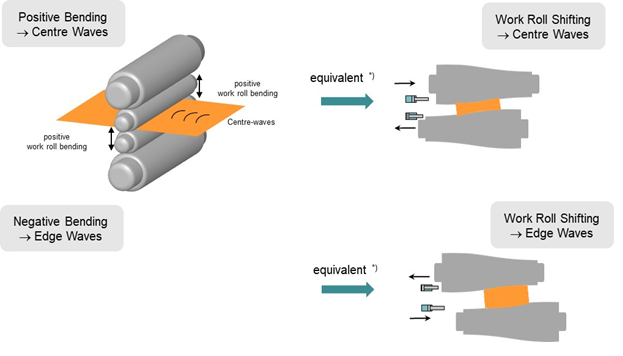

Even without a concrete project, customers use the know-how of pa-innovations to gain fundamental knowledge from the perspective of an automation engineer. In such courses e.g. basic knowledge of the deformation in the roll gap, basic effects of actuators, the interaction of several roll stands regarding mass flow etc. are imparted.

For this purpose courses like e.g.

- Technological aspects of control of a hot strip mill/cold rolling mill

- Requirements for a pass schedule calculation model of a hot strip mill/cold rolling mill

can be offered.