Medium Width Hot Rolling Mill Avon Steel, India

Level 1 automation System, technological control system, level 2 system

- Date: January 2017

- Customer: Avon Steel Industries (P) Ltd., Ludhiana, Punjab, India

- Project Type: Level 1 and Level 2 Automation

About the Project

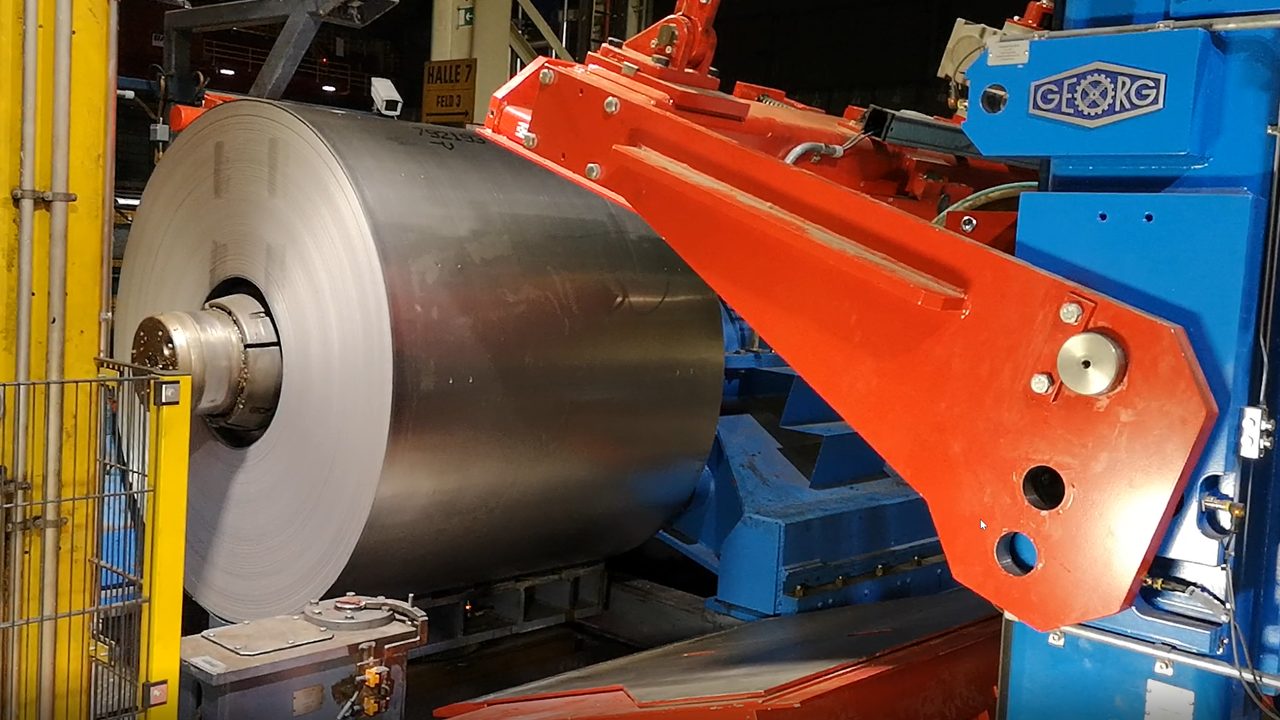

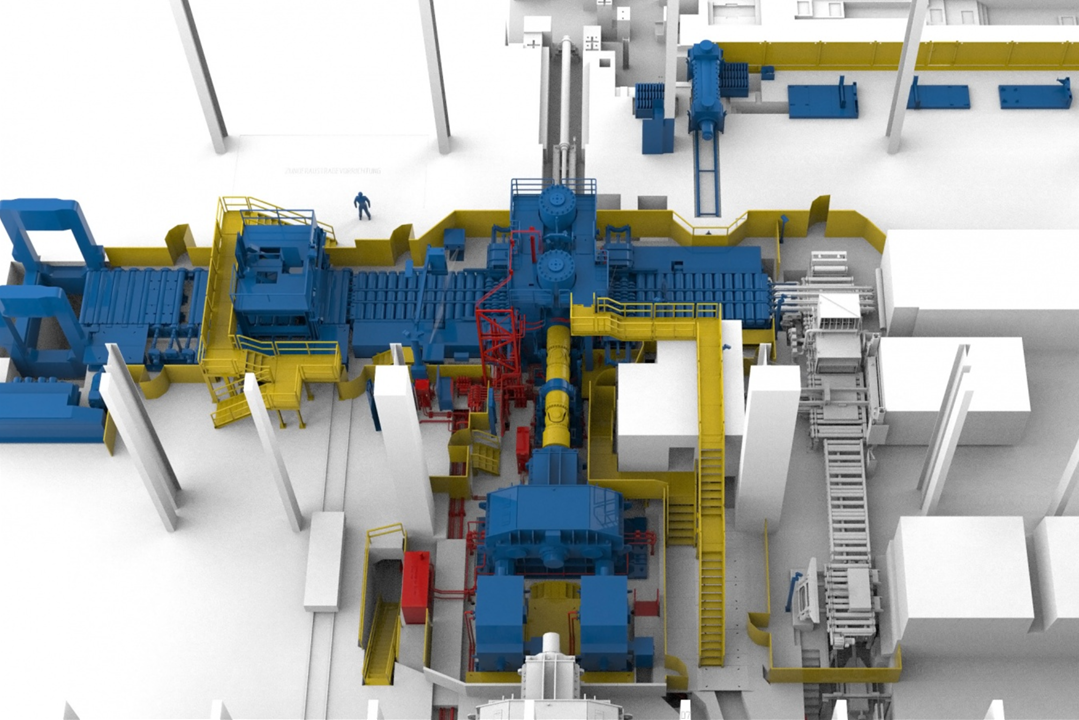

In January 2017 pa-innovations GmbH signed a contract with Avon Steel Industries (P) Ltd. for the supply of a level 1 system for hydraulic gap control, automatic thickness control, media systems and mill visualisation as well as a level 2 system for the setup of the 6-stand medium width hot strip mill in Ludhiana, Punjab, India.

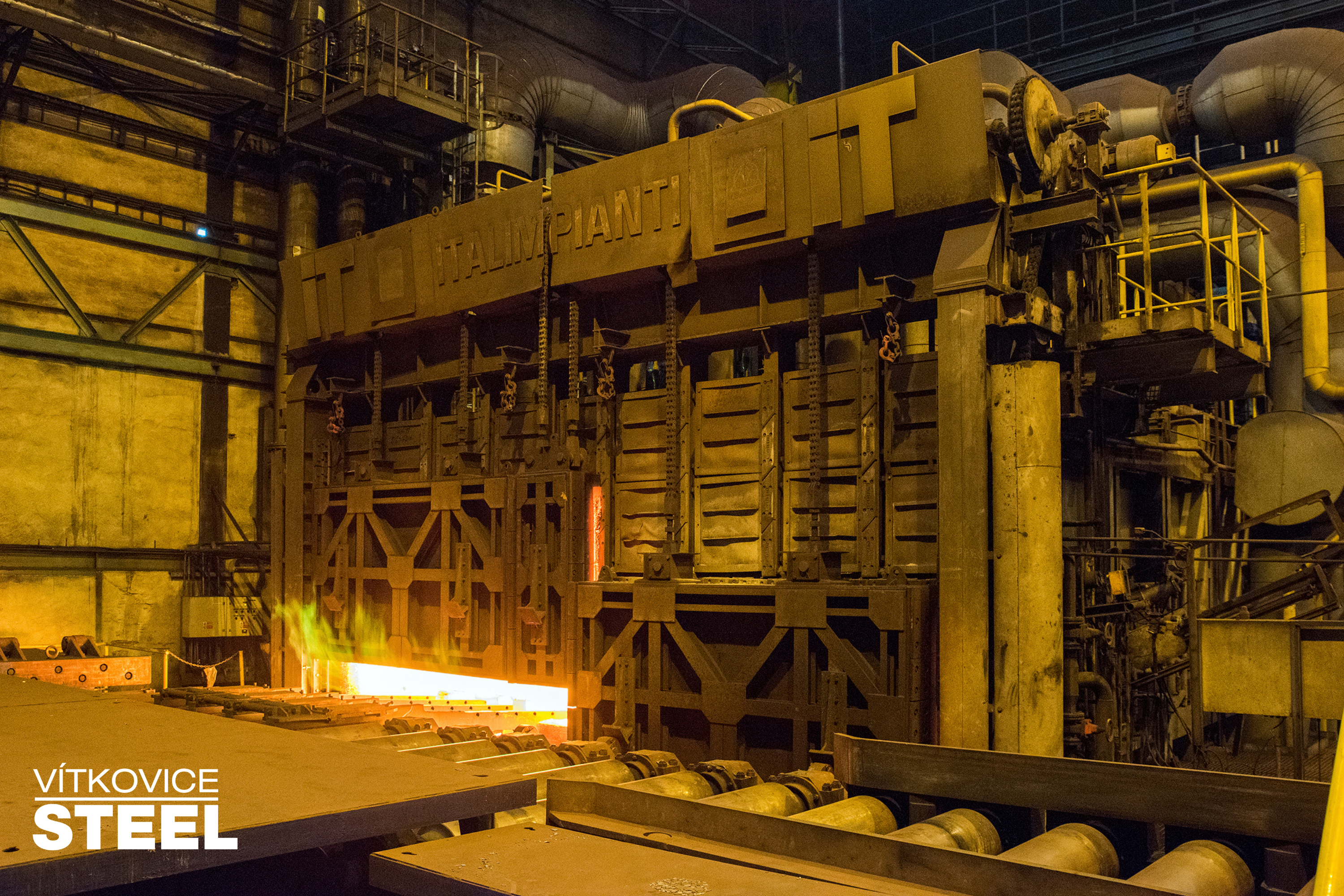

In the course of this project, the electromechanical adjustment systems were replaced by hydraulic cylinders. In addition to the new media systems, a new thickness measuring device was also implemented.

pa-innovations used a state-of-the-art thickness control system as well as a level 2 system tailored for this specific mill for the automatic pass schedule setting and automatic recording of quality data, downtimes and production data.

The supply included:

- the entire hardware,

- the planning of erection and the erection supervision,

- the software for technological control functions, media systems and entire visualisation,

- the software for the level 2 quality data and pass schedule handling system,

- the commissioning and optimisation.

The software for technological control functions include:

- automatic roll gap calibration,

- automatic mill stretch data acquisition,

- thickness control for the individuals stands (stretch compensation),

- thickness feedback control via thickness gauge behind last stand,

- strip-tracking for automatic thread-in and thread-out,

- strip segment specific quality data acquisition.

The level 2 system includes:

- pass schedule data handling and

- automatic pass schedule selection as per primary data,

- restoring of pass schedule data,

- automatic reporting of quality data, down-time and production data including long-term archiving,

- environment for a future extension to fully automatic pass schedule calculation.

The entire shutdown for the mechanical modification and the installation of the new automation system was scheduled for October 2017 for a period of three weeks. The first salable coil was produced 3 days before the planned end of the shutdown. On November 27, 2017, pa-innovations received the final acceptance after an extremely successful commissioning and optimization phase and the training of the engineers and operation personal.