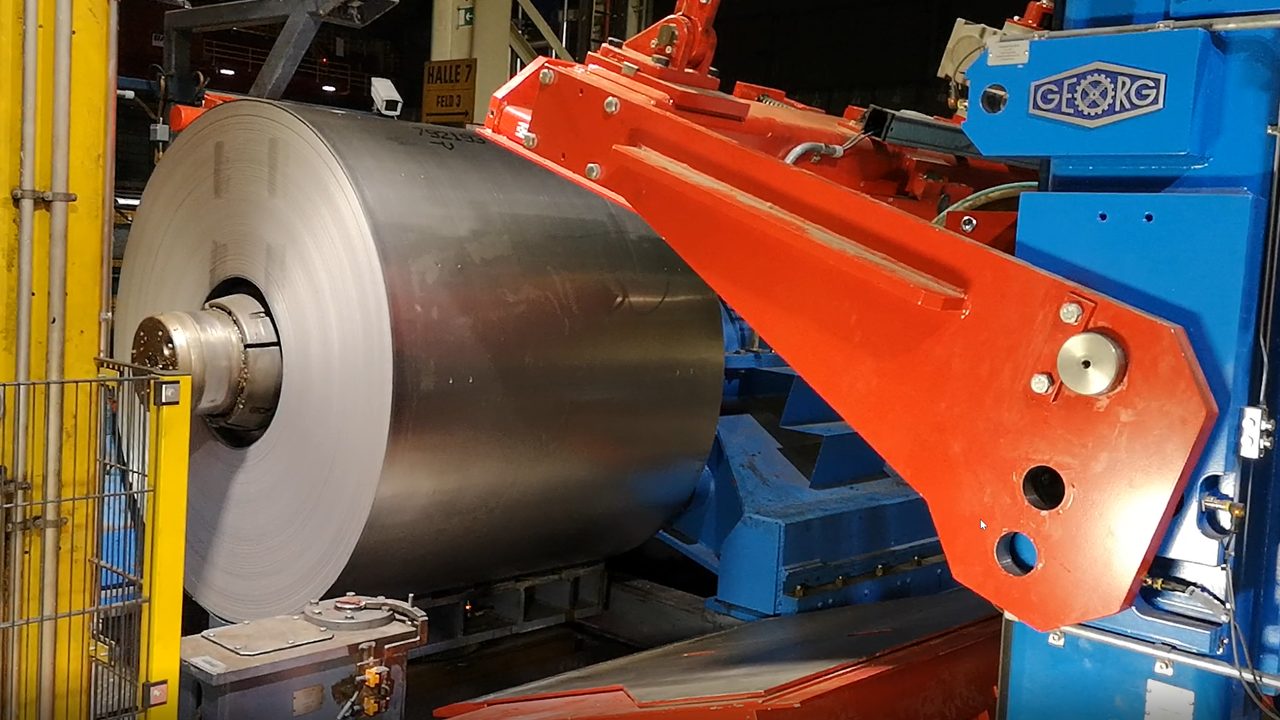

Heavy plate rolling mill, voestalpine Grobblech, Austria

Level 1 automation and technological control system for the new mill stand at voestalpine Grobblech in Linz

- Date: November 2015

- Customer: voestalpine Grobblech GmbH, Austria

- Project Typ: Level 1 automation and technological control system for rolling mill

About the Project

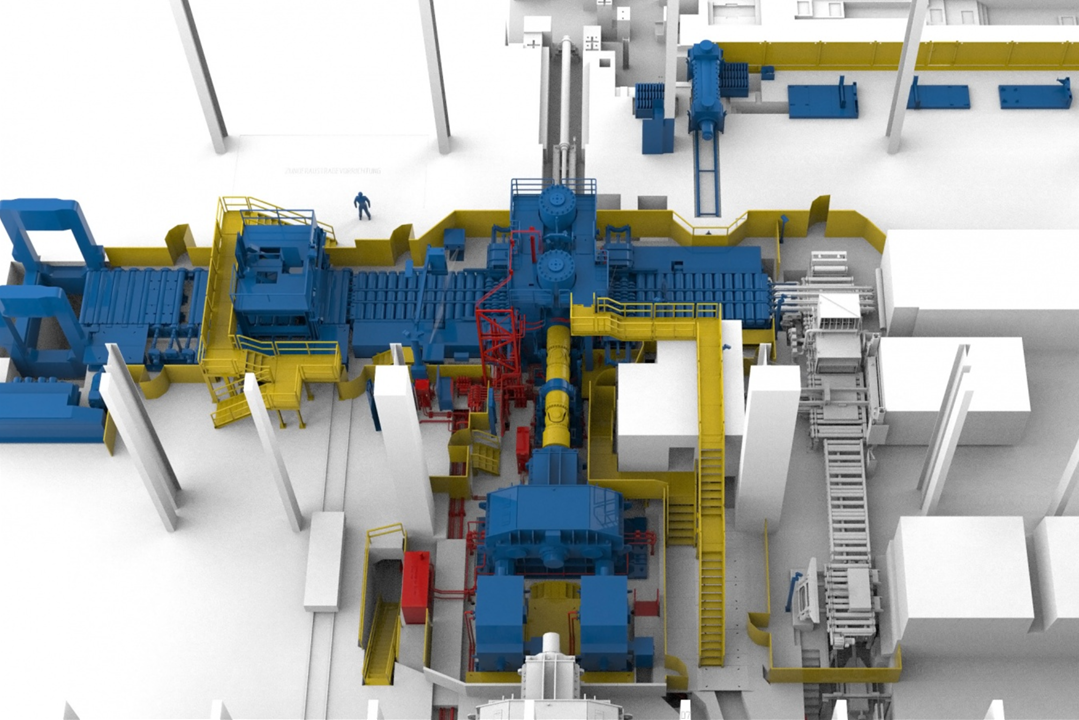

In december 2013 pa-innovations GmbH was awarded by voestalpine Grobblech GmbH in Linz, Austria for the supply of the automation of the new mill stand of their existing plate mill.

The scope of supply included:

- all actuator controls,

- automatic thickness control including “tail- & head end shaping” for the enhancement of the plate’s rectangularity,

- roll change,

- PLC for central switching functions

- safety control system,

- pre-erection and integration test at the test-field,

- Erection engineering, erection, commissioning and

- Optimisation.

Due to the extremely short time for the dismantling of the old mill stand and erecting the new mill stand, it was decided to build up the entire new mill stand at a test-field next to the final destination. During these tests, the entire automatic functions for roll gap adjustment, work-roll bending and shifting system, calibration etc. could already be commissioned before the final installation at the foreseen destination. The technological control system was realised on a high performant multicore processor system in order to fulfil the requirements for the control dynamics. For the safety control system a Siemens S7410h was used. Movements within the safety area were realised with a portable panel based on RFID-tags.

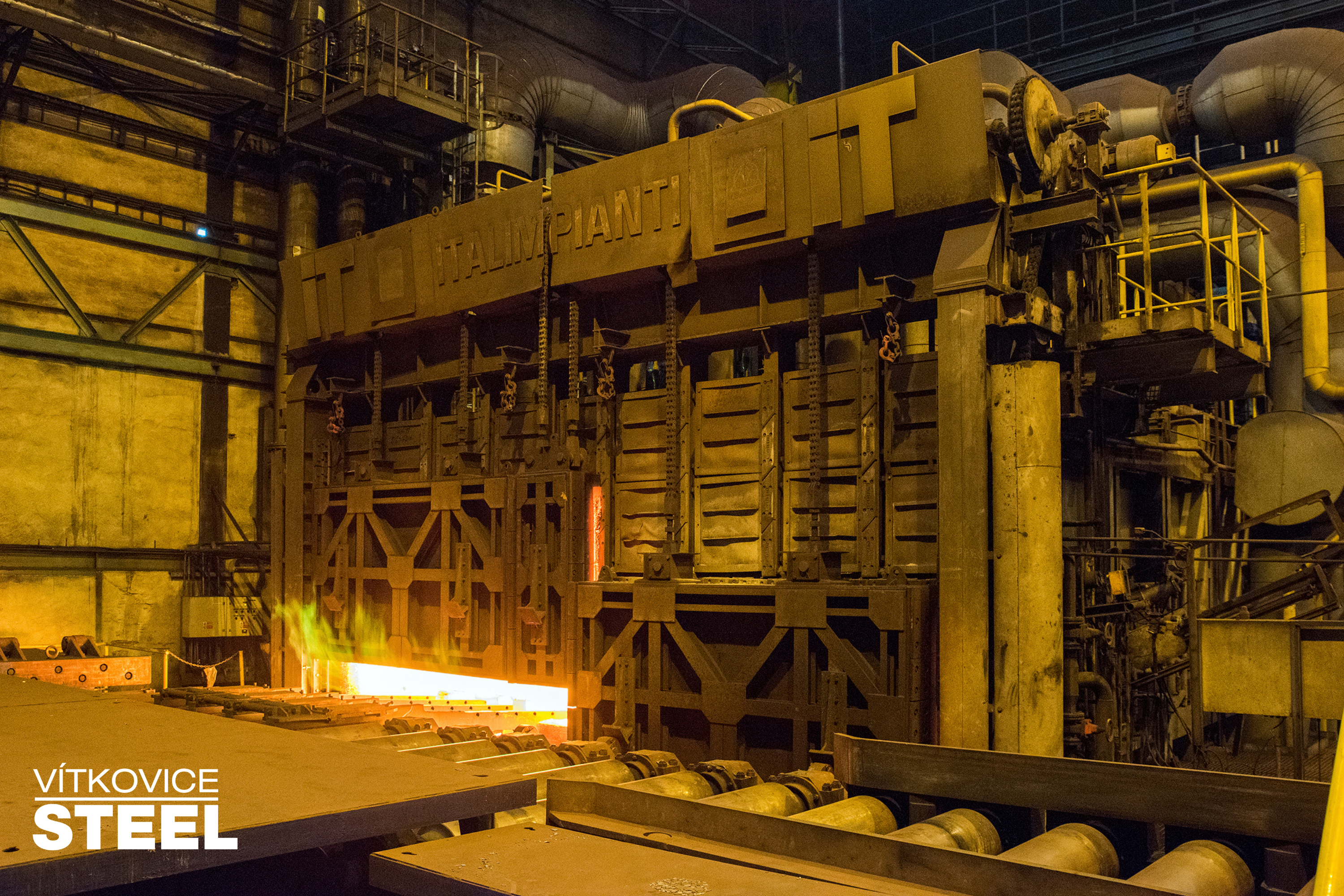

The mill produced the first plate already in fully automatic mode after a shut-down time of 31 days – within this period the old mill stand was dismantled and the new mill stand was build up.