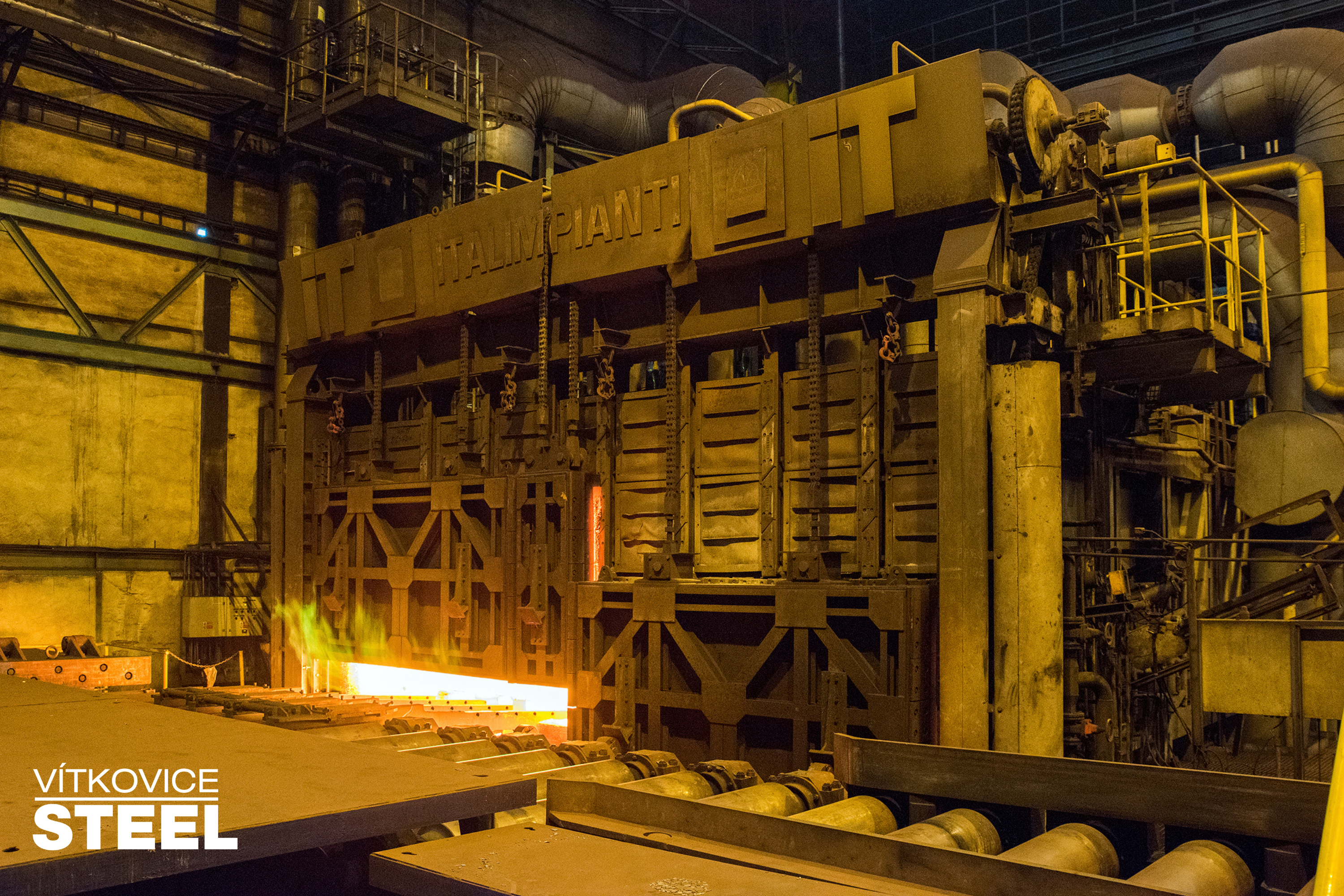

Plate Mill VÍTKOVICE STEEL, Czech Republic

New furnace model for the slab heating furnace of the plate mill stand

- Date: September 2019

- Customer: Vitkovice Steel a.s.

- Project Type: Level 2 System

About the Project

In September 2019 pa-innovations GmbH signed a contract with VÍTKOVICE STEEL a.s. Ostrava, Czech Republic for the supply of a new furnace model for their pusher type furnace no. 3 of the plate mill. This contract was an amendment of the contract for a new level 2 setup system for the plate mill which was implemented in summer 2019 very successful and which was a follow-up-project to the implementation of the new technological control system of their plate mill in the year 2015.

All these individual projects were parts of a gradual modernisation campaign in order to ensure high availability, high throughput and high quality and were all carried out by pa-innovations.

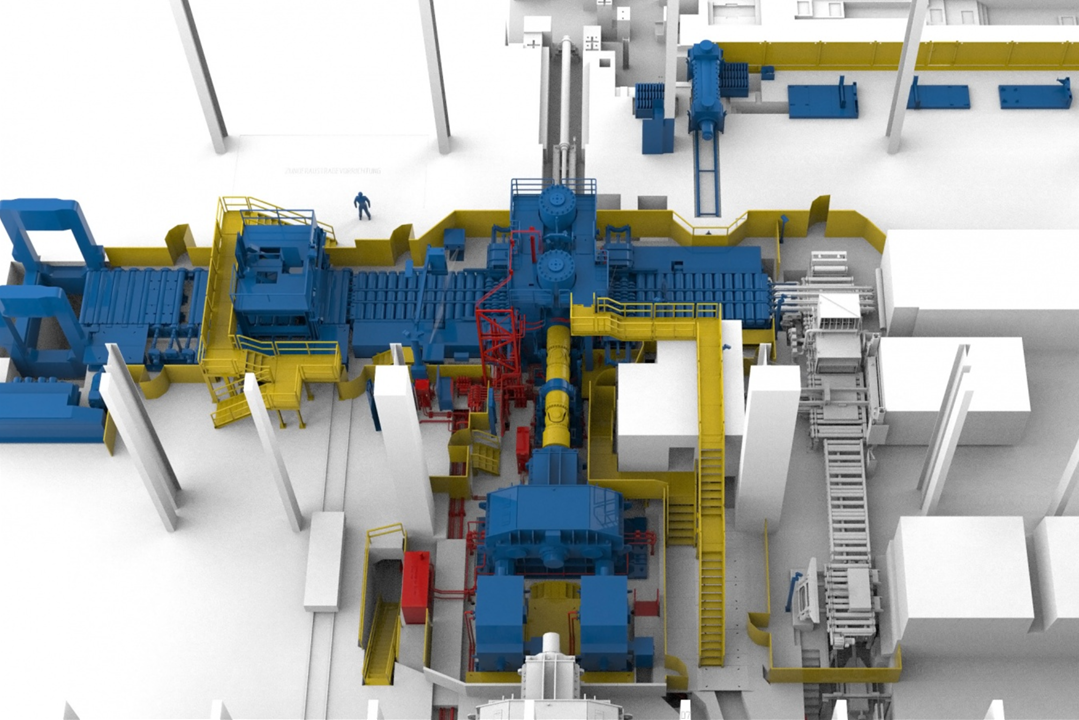

The new furnace level 2 is a special development of pa-innovations for retrofitting of old furnaces as well as for new furnaces and includes the following features:

- 2D slab temperature model

- Discharge time prediction model

- Throughput-oriented furnace temperature control

- Full automatic discharging in combination with rolling mill time coordination model

- 3D – visualisation

- Delay handling

The new model and visualisation was integrated into the level 2 system of pa-innovations provided for the plate mill.