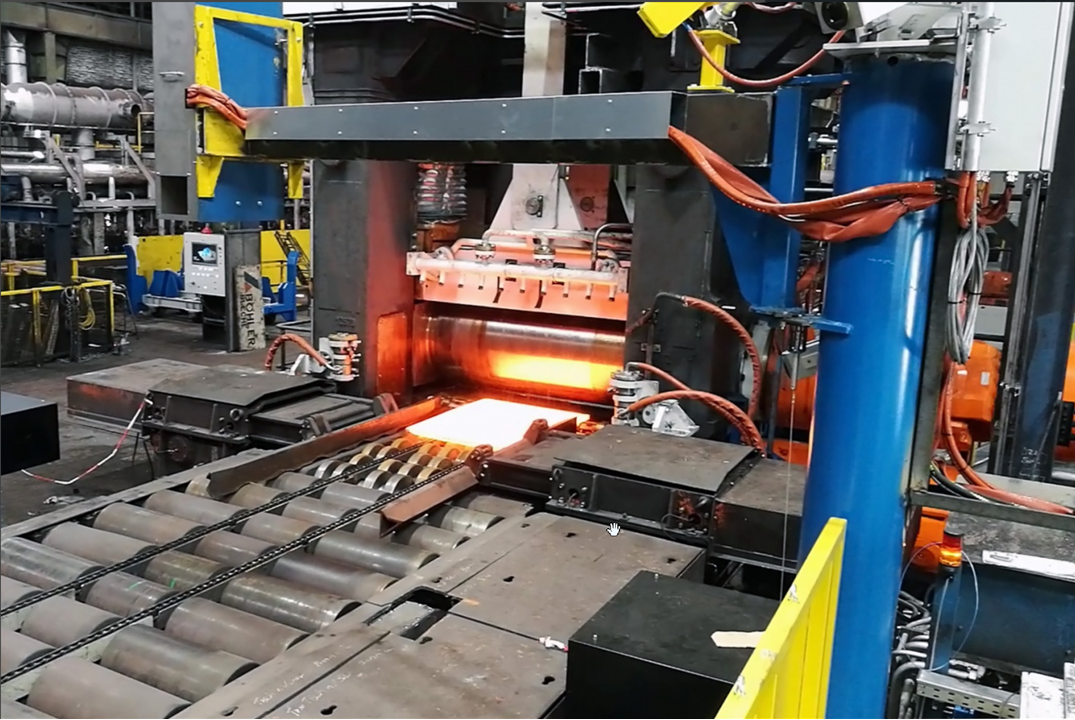

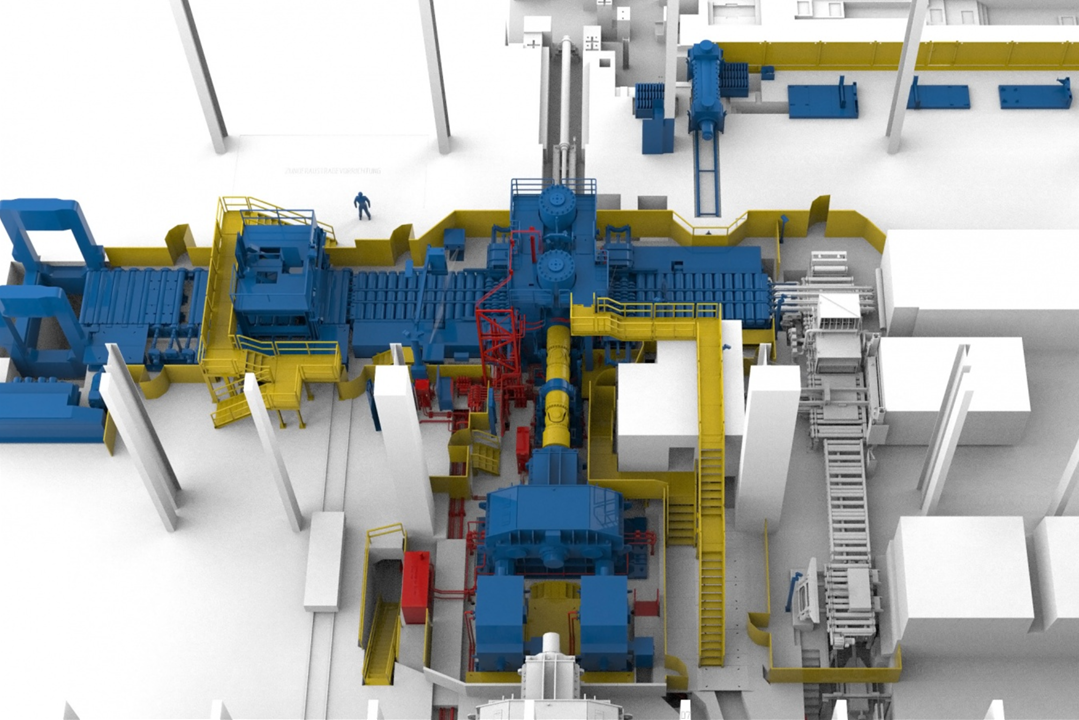

DUO3 rolling mill, voestalpine Böhler Bleche, Austria

Level 1 and Level 2 automation and technological control system for the conversion from a TRIO rolling stand to a DUO rolling stand

- Date: August 2018

- Customer: voestalpine Böhler Bleche, Austria

- Project Type: Level 1 und Level 2 Automation

About the Project

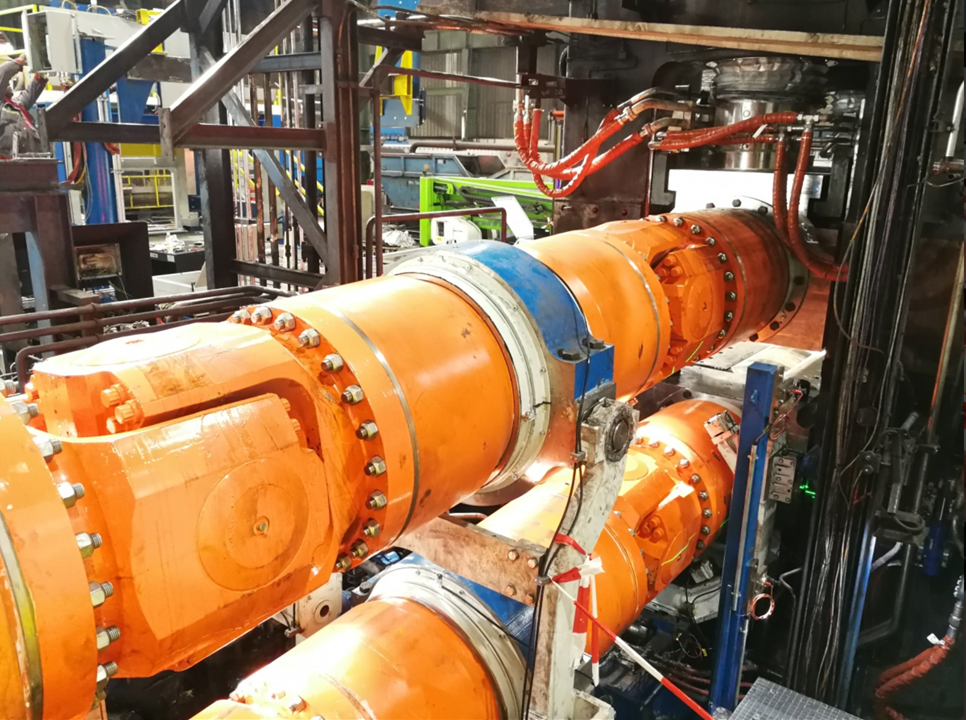

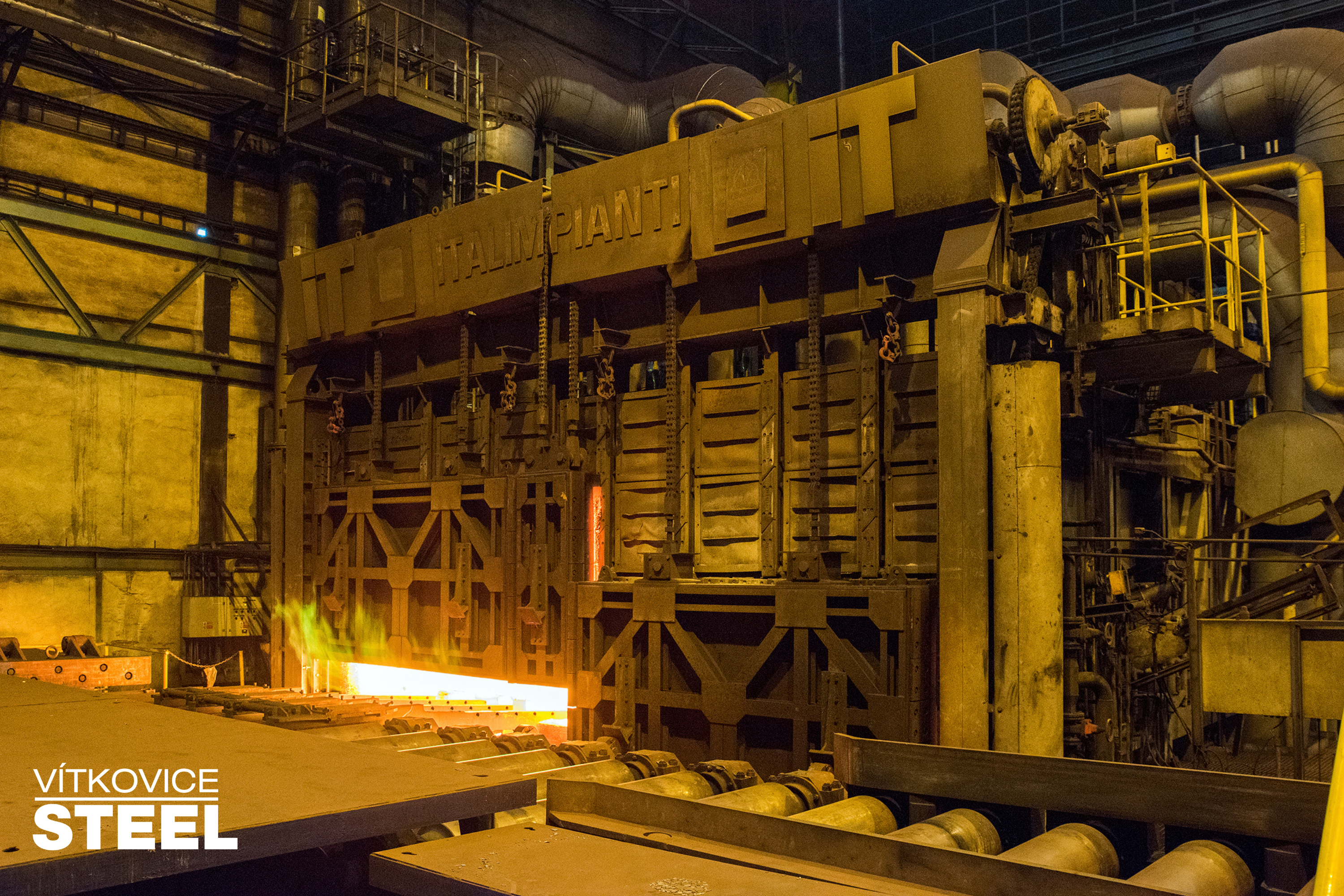

At the beginning of 2018 pa-innovations GmbH received the order for the delivery of the automation for the conversion of the TRIO mill stand to a DUO mill stand at voestalpine Böhler Bleche GmbH & CO KG in Hönigsberg, Austria.

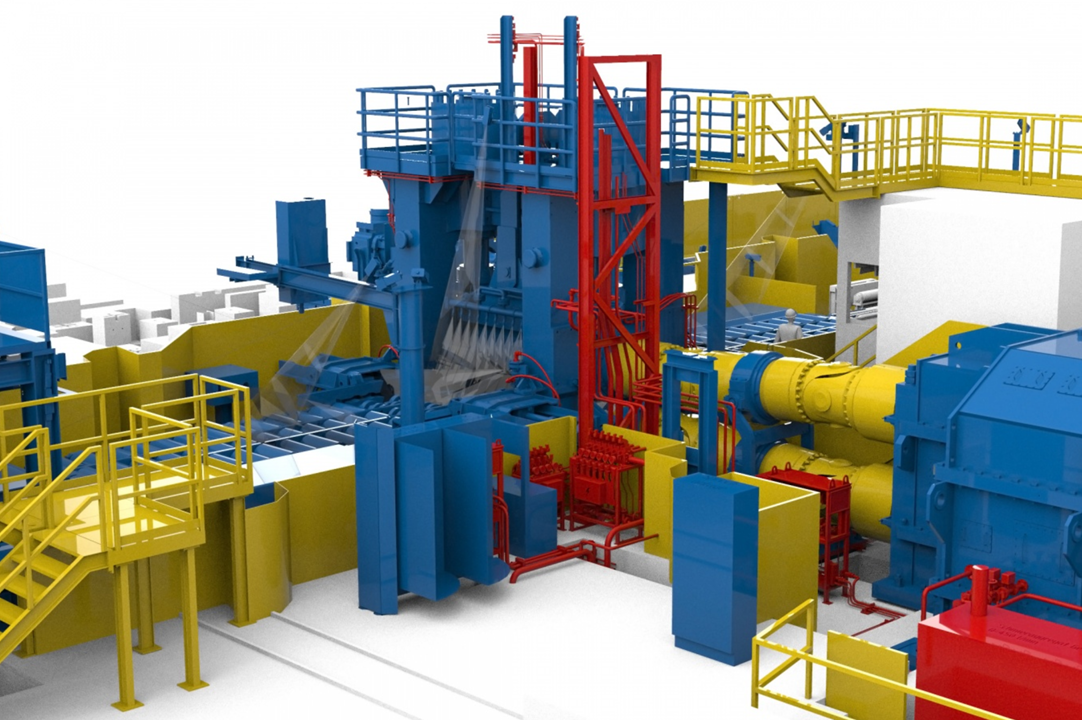

The delivery from pa-innovations GmbH included:

- Function description including control desk design and operating philosophy,

- Level 2 system and complete 3-D visualization system,

- Entire Level 1 software,

- Commissioning and optimization,

- Training of maintenance engineers and operating personnel.

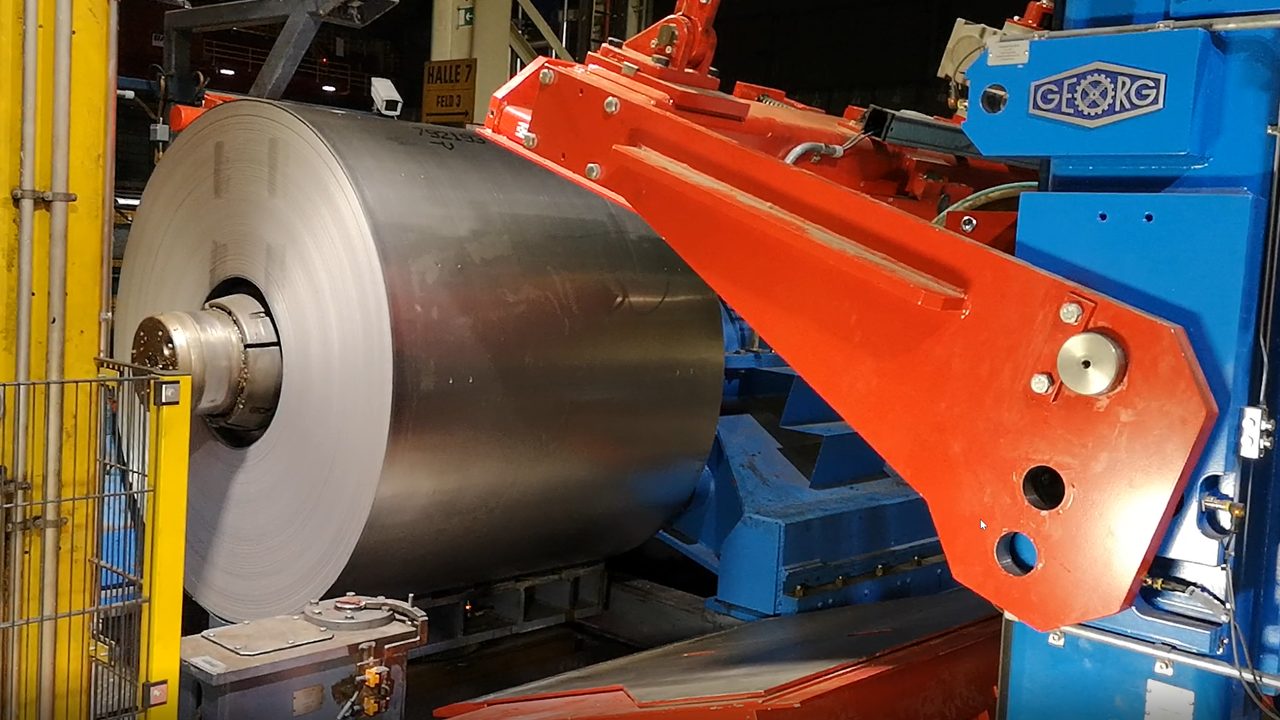

A key argument for the decision in favor of automation technology from pa-innovations was the good experience with the delivery of automation solutions for

- the modernization of the DUO2 rolling mill in the year 2013 (level 1 and level 2 systems) and

- the rolling mill for high-speed steel in the year 2016.

voestalpine Böhler Bleche appreciates the high level of competence of the specialists of pa-innovations GmbH.Like many other similar projects, the project was carried out together with BUMA Engineering and Plant Construction as a mechanical partner. Only due to the well proven team of these two companies as well as Kremsmüller as electrical partner, this project could be carried out within a short time of 6 months from awarding to commissioning and optimization.