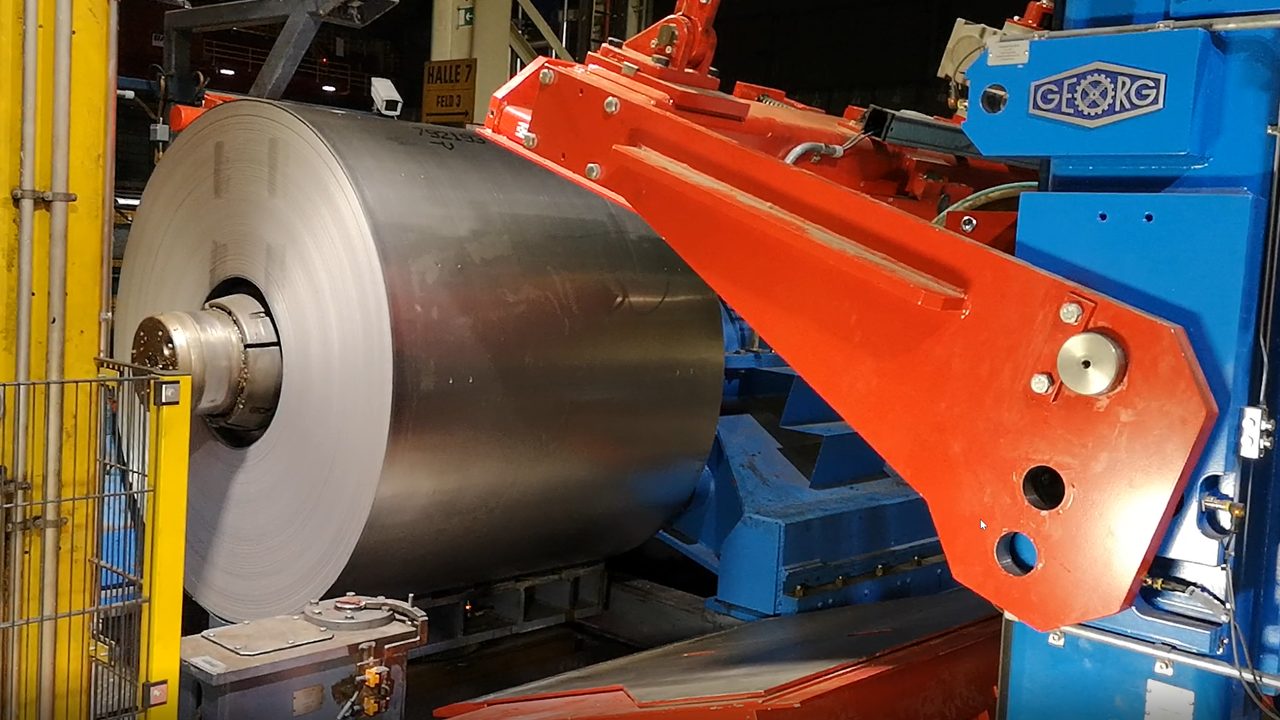

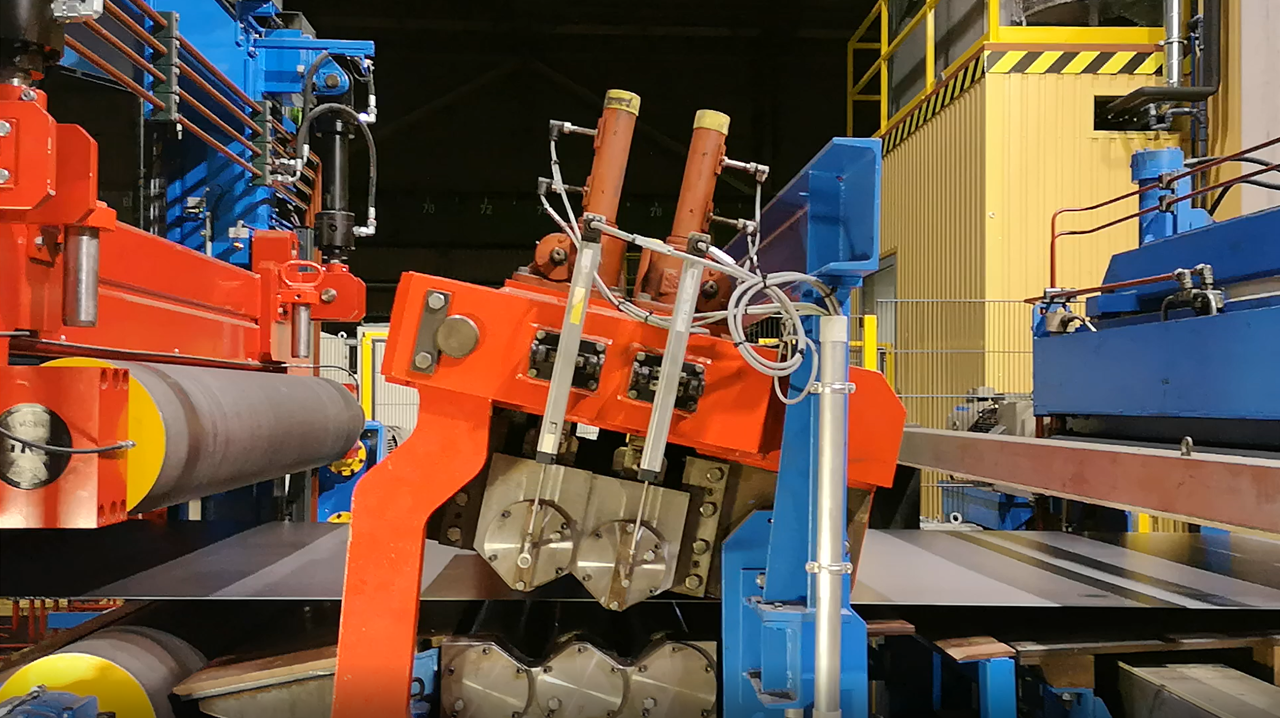

Inspection Line No. 2 voestalpine stahl GmbH

Electrics and Automation:

- Functional control and safety control on PCS7 including visualization

- Control cabinets, drive systems including assembly

- Date: January 2017

- Customer: voestalpine stahl GmbH, Austria

- Project Type: Electrics and Automation

About the Project

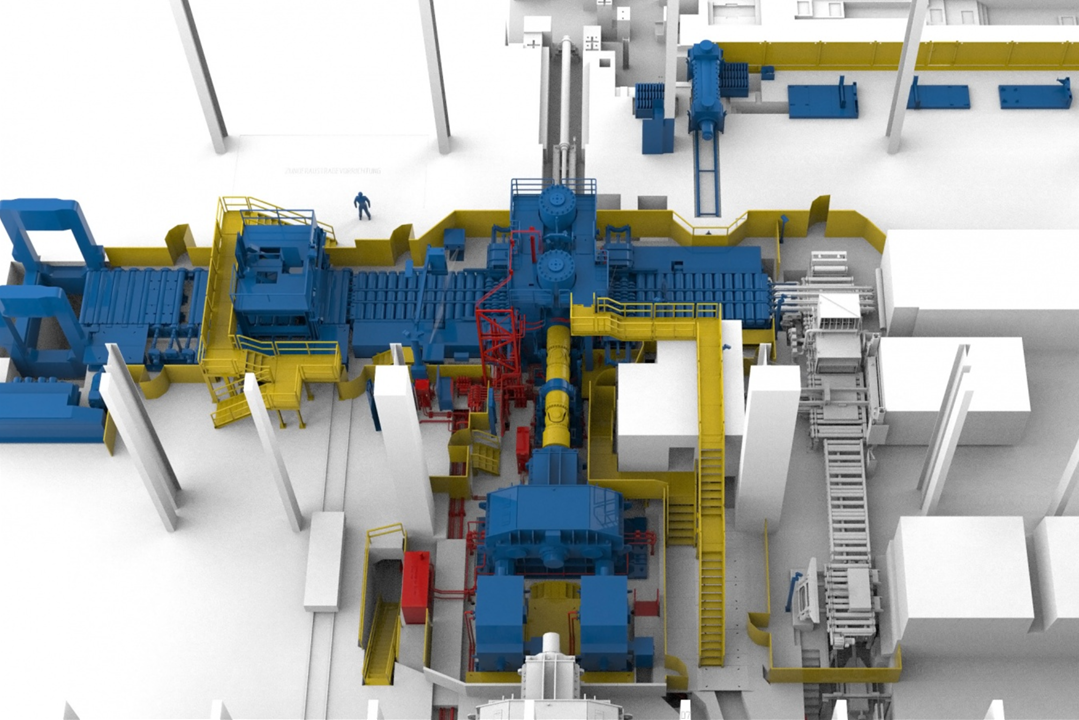

At the beginning of 2017 pa-innovations got the purchase order as general contractor for the supply of electrics and automation for the modernisation of the inspection line no. 2 at the finishing area of voestalpine Stahl GmbH in Linz, Austria.

The supply of pa-innovations GmbH included:

- the functional description and operating philosophy,

- software for:

the entire functional controls,

the laser-welding-machine,

the electrostatic oiling machine,

the strapping machine,

the safety control

on PCS7 - the visualisation on WinCC and TIA (Touch Panels)

- the electrical engineering,

- the supply of cabinets and drive systems,

- the erection, commissioning and optimisation.

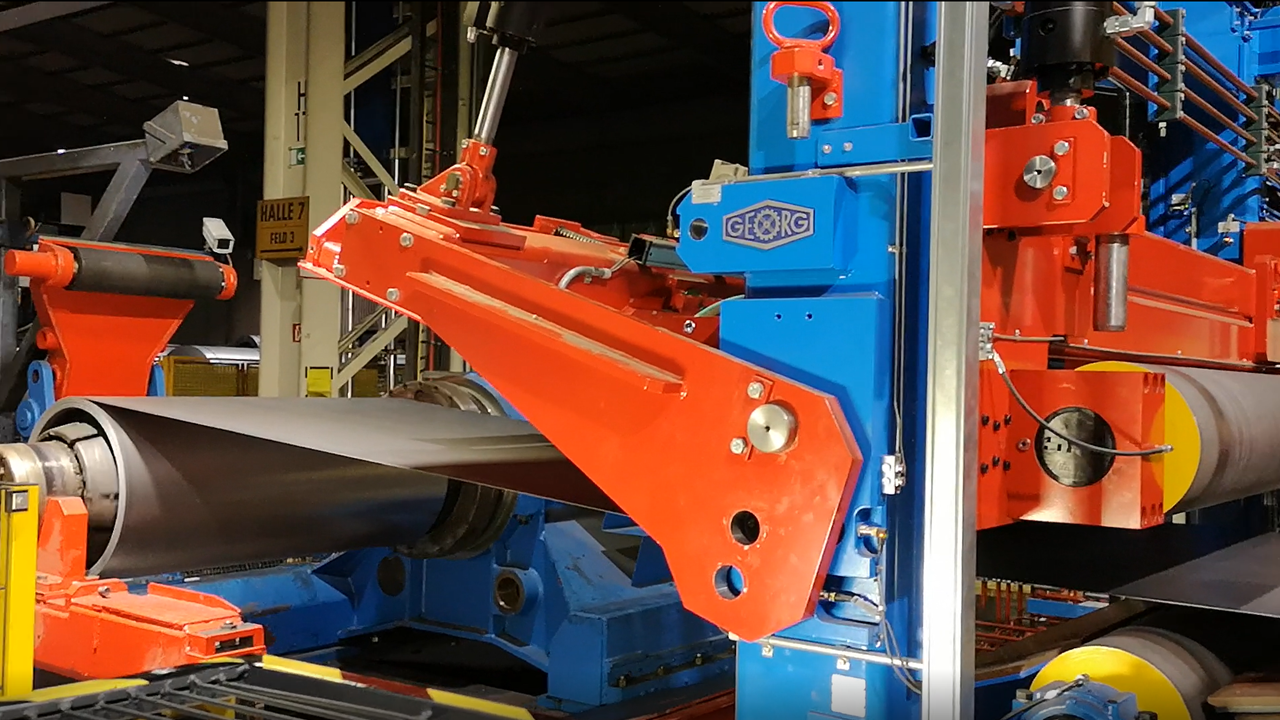

A major reason for the decision in favor of automation technology from pa-innovations were the efficient solutions for the function block library, the operation and diagnosis system and the excellent experience in the delivery and implementation of the software for the inspection line no. 6 in the year 2013.

voestalpine Stahl particularly appreciated the integrated solutions from pa-innovations based on PCS7, for the whole range from standard control functions until package units. In April 2020, this ultimately led to another purchase order for the modernization of inspection line no. 4.