Level 2 Systems for Cold Rolling Facilities Tatmetal, Turkey

Level 2 Systeme:

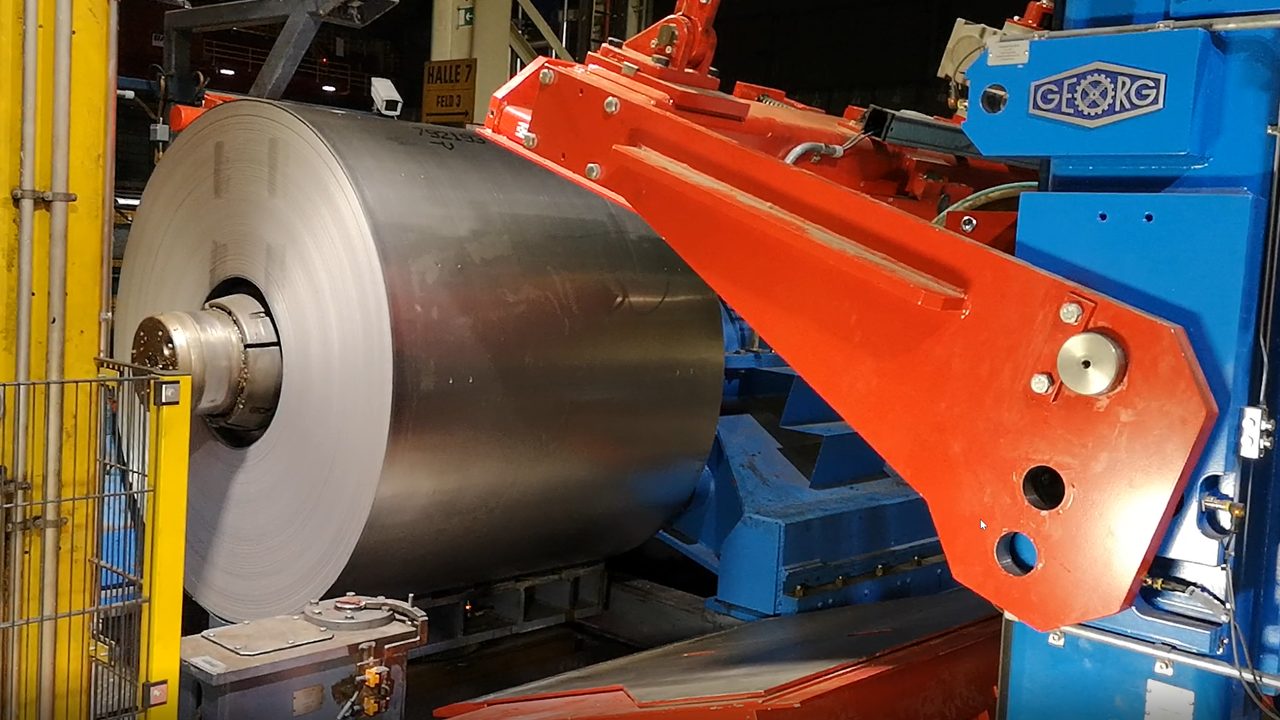

- two 6-high reversing mills

- skin pass mill

- color coating line

- galvanizing line

- Date: 2017 – 2020

- Customer: Tatmetal, Ereğli, Turkey

- Project Typ: Level 2 Systems

About the Project

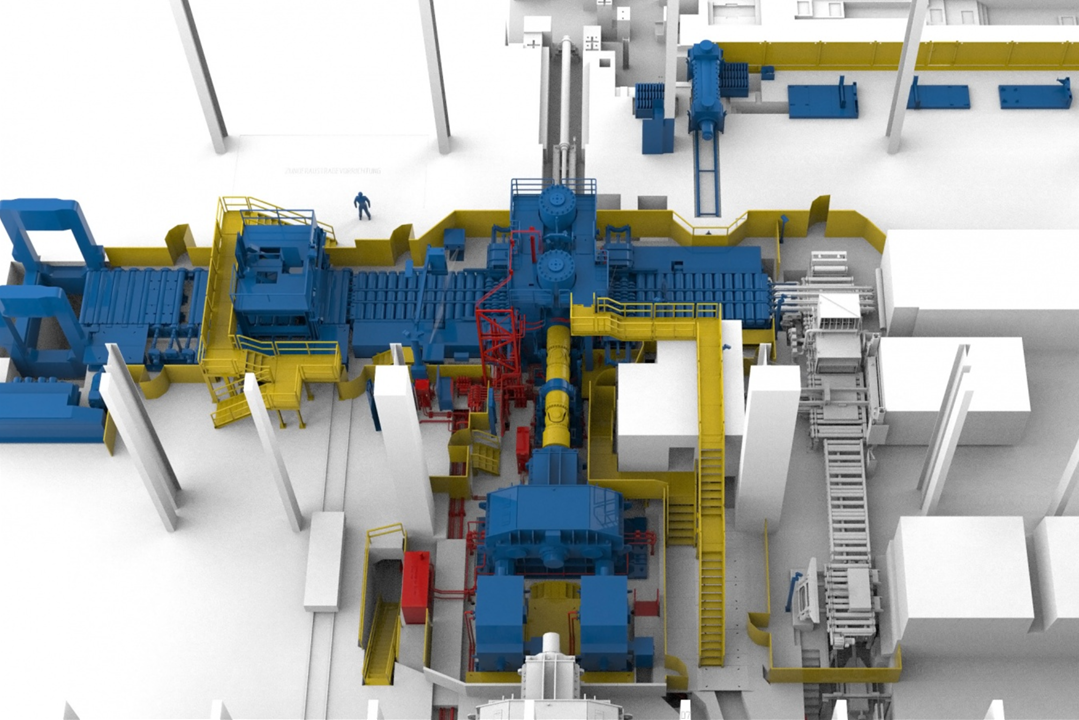

In the year 2017 pa-innovations was awarded a contract for the delivery of level 2 pass schedule setting systems for

- the Reversing Cold Mill No. 1 (RCM1),

- the Reversing Cold Mill No. 2 (RCM2) and

- the Skin Pass Mill of

TATMETAL at the Black Sea in Ereğli, Turkey.

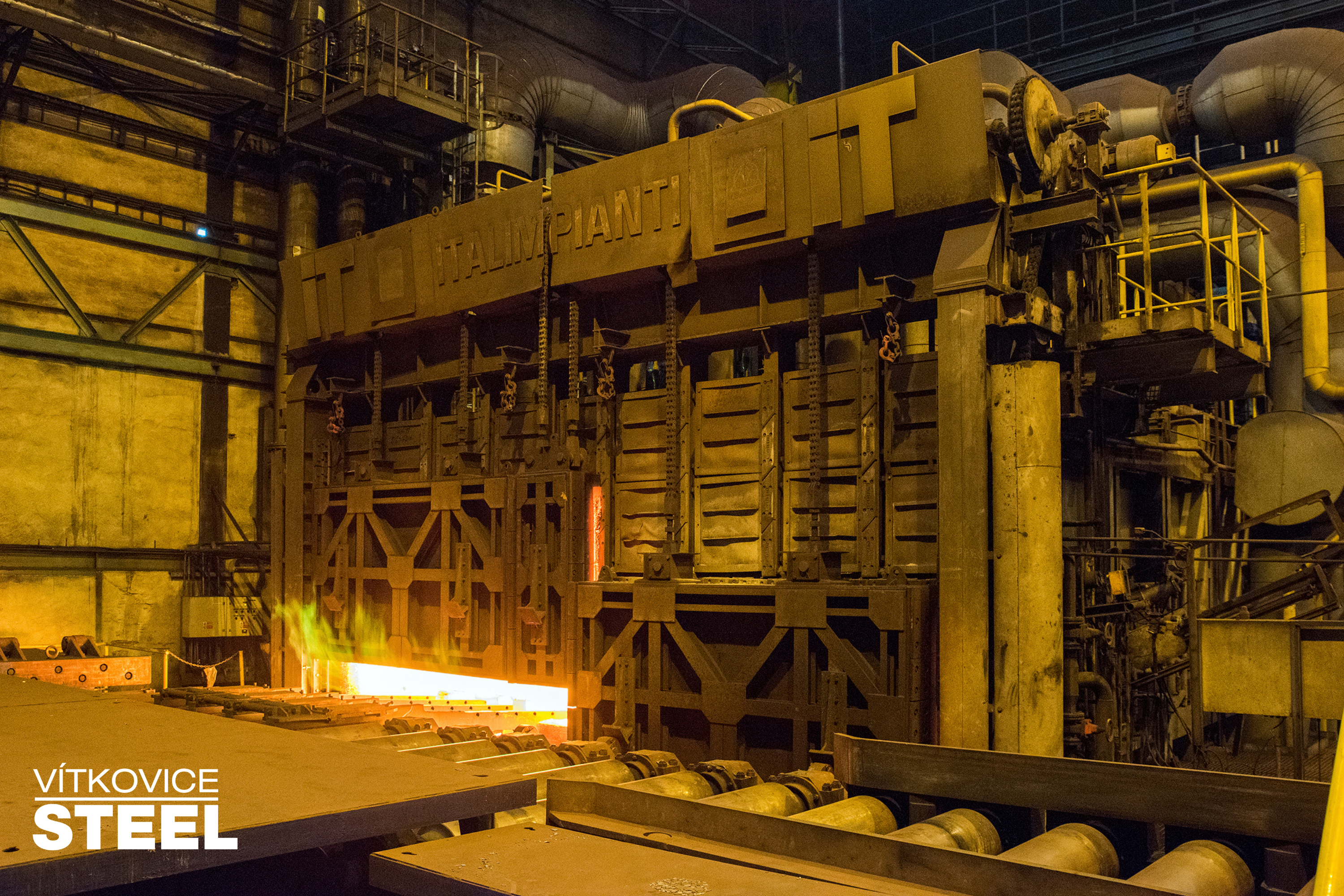

After the highly successful implementation of these projects, TATMETAL decided in the year 2019 to purchase also level 2 systems for

- their Colour Coating Line (CCL) and

- their Continuous Galvanizing Line No. 1 (CGL1)

Both, RCM1 and RCM2 are based on 6-hi technology in order to serve the high quality demands for export. pa-innovations convinced TATMETAL about the automatic pass schedule calculation based on physical/mathematical models including advanced algorithms for thin gauges and automatic adaptation.

The Skin Pass Mill was equipped with a fix pass schedule system extended by a model for the flatness actuator setting with automatic adaptation.

The Colour Coating Line (CCL) is equipped with a look-up table system and automatic adaptation algorithms for the coater force based on automatic learning from operation-experts.

Similar to the CCL, the Continuous Galvanizing Line No. 1 (CGL1) was equipped with a look-up table system and automatic adaptation algorithms for the annealing temperature also based on automatic learning from operation-experts.

All the level 2 systems are fit up with comprehensive reporting systems (production reports, down-time reports, quality reports) in order to ensure continuous quality tracking.